Scientific Note: Effects of Nuclei Type on Characteristics of Creamed Honey

Abstract

Creamed honey is a non-liquid form of honey. This type of honey is produced mainly by adding nuclei (i.e. previous creamed honey) to liquid honey. In this research, chemical characteristics of creamed honey produced using two nuclei types; 10% of creamed honey (M1), and 2.4% of powdered glucose (M2) at a storage temperature of 5°C were investigated. The sugar content, pH, and water percent were chemically analyzed. The results showed that sucrose, fructose and moisture percents were significantly higher in creamed honey produced using M1 by 1.09, 1.69 and 1.65%, respectively than M2. On the other hand, creamed honey produced using M2 had significantly higher glucose percent and pH by 2.4% and 0.53, respectively than M1. The study highlighted the noticeable impacts of nuclei type on characteristics of creamed honey. The results of this study have a special importance to creamed honey producers.

Keywords:

Bee honey, Creamed, Glucose, Nuclei, CloverINTRODUCTION

Bee honey is valuable food with many nutritional and medicinal advantages (e.g. Ahuja and Ahuja, 2010). The liquid form of bee honey has some problems including; the occurrence of natural crystallization at room temperatures (Zamora and Chirife, 2006), and hence the rapid granulation. Also, this form of honey has low spreadability. Therefore, turning the liquid honey into creamed honey is a suitable way to solve such problems, although the low thermal stability of creamed honey especially at high temperatures (Karasua et al., 2015). The production of creamed honey depends on multi-factors including; nuclei type, storing temperature, honey type, and some specific properties of honey. These properties are glucose content and melezitose (Bogdanov, 1993), and the glucose/ water ratio (Austin, 1953). It is likely that nutritional properties of creamed honey are equal to those of liquid one.

Using creamed honey as nuclei to liquid honey is the original way to produce creamed honey according to Dyce (1975). In Dyce’s method, about 5~10% of the nuclei should be added to liquid honey and storing temperature of 14°C should be used to obtain creamed honey. Another type of nuclei, powdered glucose, was used by Chen et al.(2009) at 0.1 percent and a storage temperature of 14°C to obtain the creamed honey from litchi honey. Recently, Abd Elhamid and Abou-Shaara (2016) have developed a simple method to obtain creamed honey from clover and cotton liquid honey using powdered monohydrous glucose at a storage temperature of 5°C. They have succeeded in obtaining this solid form of honey after 15 and 27 days when 2.4% of powdered glucose was added to liquid cotton and clover honey, respectively. So far, a comparison between the chemical characteristics of the creamed honey produced using standard nuclei type (fully crystallized or creamed honey) and new nuclei type (powdered monohydrous glucose) at a storage temperature of 5°C has not been done. Therefore, the study aimed to present this comparison to highlight the effects of nuclei type on creamed honey.

MATERIALS AND METHODS

Creamed honey production

Clover honey collected from three apiaries at El-Behera governorate, Egypt were used in the experiments. 500 grams of honey from each apiary was turned into creamed honey, 250 grams using creamed honey as nuclei (denoted as M1), and the other 250 grams using powdered glucose as nuclei according to Abou-Shaara and Abd Elhamid (2016) method (denoted as M2). Briefly, in M1, 10% of creamed honey was added to liquid honey while in M2, 2.4% of powdered monohydrous glucose was added to liquid honey. After mixing the liquid honey with nuclei, the honey was left at room temperature for 24 hours and then the honey was stored in refrigerator (temperature about 5°C) until full crystallization.

Chemical analysis

Creamed honeys produced using the two methods were subjected to the chemical analysis following the methods used by Abou-Shaara and Abd Elhamid (2016) in accordance with AOAC (1990 and 2000). Briefly, honey samples were warmed at 40±1°C for 30 min prior the analysis. The moisture percent was determined using drying method using hot air oven at 70°C (2.0g of each sample). The pH was measured using a digital pH meter (Model HI 9321; HANNA, Portugal at 40°C). The sucrose content was determined using Layne-Enyon method while glucose and fructose were determined using the resorcinol reagent method.

Statistical analysis

All means were expressed as means±standard errors (S.E). SAS (version 9.1.3, 2004) was used to perform the statistical analysis. Means were compared using t-test at significance level of 0.05.

RESULTS AND DISCUSSION

Percent of sugars

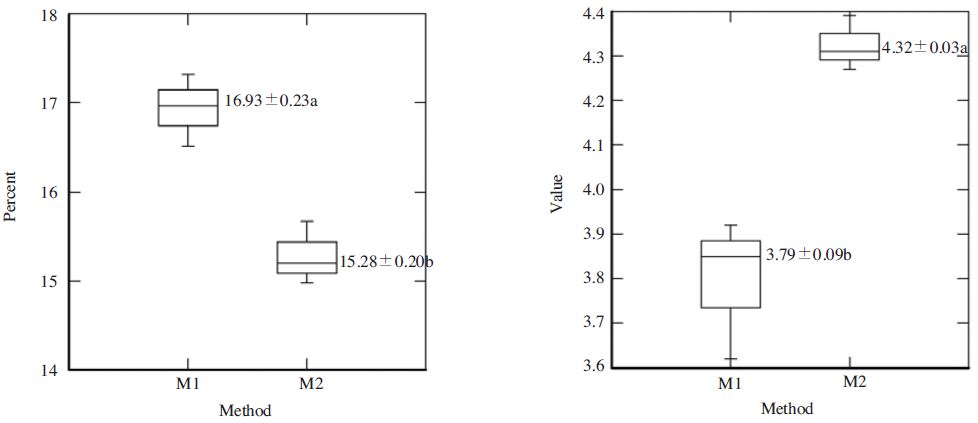

Creamed honey produced either by using creamed honey as nuclei (M1) or using glucose powder (M2) at a storage temperature of 5°C showed variations in the percent of sugars. As shown in Fig. 1, significant variations were detected between M1 and M2 according to t-test (for sucrose; t statistic= 12.82 and P=0.0002, for fructose; t statistic=5.17 and P=0.006, and for glucose; t statistic= 6.46 and P=0.003), for all sugars df=4 and P<0.05. Honey produced using M1 had a higher percent of sucrose and fructose than honey produced using M2 by 1.09 and 1.69%, respectively, but vice versa in regard to glucose, and the difference was 2.4%. It is clear that honey produced using M2 had a noticeable higher percent of glucose than that produced using M1. This could be explained by adding powdered glucose to liquid honey during production process. Also, it is clear that honey sugars can be impacted by nuclei type. Therefore, the increase in glucose and fructose in M1 honey can be explained by adding creamed honey as nuclei, which contains glucose, fructose and sucrose. While powdered glucose in M2 honey impacted only glucose content.

Variations between creamed honey produced using two nuclei types; creamed honey (M1), and powdered glucose (M2). Left: Variations in percents of fructose and glucose, and Right: Variations in percent of sucrose. Means and their standard errors are presented. All means are significantly different according to t-test.

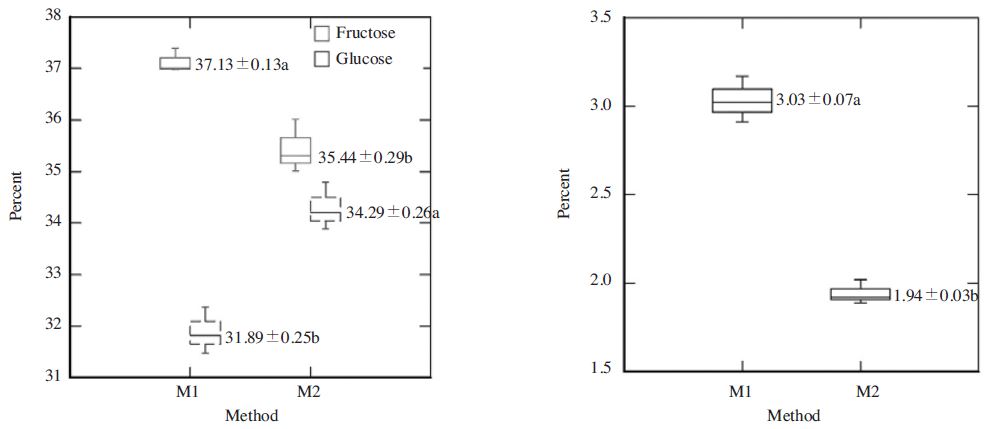

Moisture percent and pH

The moisture percent of M1 honey was significantly higher than M2 honey while pH value was significantly higher in M2 honey (Fig. 2), according to t-test (for moisture percent; t statistic=5.31 and P=0.006, and for pH; t statistic=3.79 and P=0.09), for moisture percent and pH df=4 and P<0.05. The differences between M1 and M2 honey was 1.65% and -0.53 for moisture percent and pH, respectively. It is apparent that nuclei type impacted these two parameters. Using creamed honey as nuclei increased moisture percent and decreased pH value while powdered glucose showed the reverse. Because creamed honey nuclei contain moisture unlike, powdered glucose, therefore the moisture percent was higher in M1 than M2 honey. Using powdered glucose as nuclei increased only moisture percent and pH value in creamed honey while all the other parameters were less than M1 honey. The increase in pH is normal especially when moisture percent had decreased. This result fits with the previous work by Abd Elhamid and Abou-Shaara (2016), where they recorded an increase in pH values when increased amounts of powdered glucose were added to liquid honey. It worth mentioning that honey produced using M2 had a more solid nature than honey produced using M1. This could be attributed to the higher amount of glucose in M2 over M1 due to the adding of powdered glucose. According to Manikis and Thrasivoulou (2001), honey with high glucose percent has an increased ability to crystallize. Such high crystallization ability could help in explaining the solid nature of M2 honey together with its low water content.

CONCLUSION

In this study, creamed honey was produced using two nuclei types (creamed honey, and powdered glucose) at a storage temperature of 5°C. Sugars (sucrose and fructose) and moisture percent were significantly higher in creamed honey produced using creamed honey as nuclei while only glucose percent and pH value were significantly higher in creamed honey produced using glucose as nuclei. The study emphasizes the essential impacts of nuclei type on the parameters of creamed honey. For creamed honey producers, it is very essential to mention the nuclei type used to produce their commercial creamed honey.

LITERATURE CITED

- Abd Elhamid, A.M., and H.F. Abou-Shaara, (2016), Producing clover and cotton creamed honey under cooling conditions and potential use as feeding to honey bee colonies, J. Apic, 31(1), p135-142.

- Ahuja, A., and V. Ahuja, (2010), Apitherapy - A sweet approach to dental diseases - Part I : Honey, J. Adv. Den. Res, 1(1), p81-86.

- AOAC, (1990), Food composition, additives and natural contaminants, In: Official methods of analysis, Helrich, K. (ed), Association of official analytical chemists international 2, 15th Edition, Arlington, VA, USA.

- AOAC, (2000), Sugars and sugar products, In: Official methods of analysis, Horwitz, W. (ed.), Association of official analytical chemists international, 2(44), 16th Edition, Washington, DC, p22-33.

- Austin, G. H., (1953), Maintaining a high quality in liquid and recrystallized honey, Can. Bee J, 61(1), p7.

- Bogdanov, S., (1993), Liquefaction of honey, Apiacta, 28, p4-10.

-

Chen, Y. W., C.-H. Lin, F.-Y. Wu, and H.-H. Chen, (2009), Rheological properties of crystallized honey prepared by a new type of nuclei, J. Food Proc. Eng, 32, p512-527.

[https://doi.org/10.1111/j.1745-4530.2007.00227.x]

- Dyce, E. J., (1975), Producing finely granulated or creamed honey, In Honey: A Comprehensive Survey, E. Crane ed, p293-306, William Heinemann Ltd., London, England.

- Karasua, S., O. S. Tokera, M. T. Yilmaza, S. Karamanb, and E. Dertlic, (2015), Thermal loop test to determine structural changes and thermal stability of creamed honey: Rheological characterization, J. Food Eng, 150, p90-98.

- Manikis, I., and A. Thrasivoulou, (2001), The relation of physicochemical characteristics of honey and the crystallization sensitive parameters, Apiacta, 36, p106-112.

-

Zamora, M. C., and J. Chirife, (2006), Determination of water activity change due to crystallization in honeys from Argentina, Posprint. Publ. def. Food Cont, 17, p59-64.

[https://doi.org/10.1016/j.foodcont.2004.09.003]