Polypropylene Compounding Compositions for Fabrication of Plastic Honeycomb Foundation

Abstract

A current situation on comb foundation suggested the use necessity of semipermanent plastic foundations. The compositions of polypropylene compound were selected for fabricating plastic honeycomb foundations with honeybee affinity and high nesting rate. To further increase the nest making, and effective method of wax coating on a molded foundation that exhibits good adhesion was proposed. The honeycomb foundation obtained from the compounding compositions was regenerable and durable. It was able to prevent environmental pollution due to the existing disposable wax foundation and contribute significantly to the practicality and economic improvement of the environment beekeeping industry.

Keywords:

Comb foundation, Honeybee affinity, Beeswax, Polypropylene compounding, Wax coatingINTRODUCTION

Recently, along with the increase in income and improved quality of life, life expectancy has been extended, and interest in healthy food has increased daily. Among them, fresh honey is an essential food along with ginseng, and the demand for it is increasing day by day. However, fresh honey without heavy metal pollution decreases due to the increase in pesticides in honey production and fine dust caused by environmental pollution (Celli and Maccagnani, 2003). In addition, as global warming is accelerating due to industrial development and an increase in the automobile exhaust gas, honey sources are rapidly decreasing due to climate change and ecosystem destruction. Honey production is continuously decreasing due to decreased number of bees and beekeepers. Honeybees have a very close relationship with humans’ living environment and lifespan, so the number of bees is a critical factor in natural environment and humans’ lifespan (Al Naggar et al., 2013). Therefore, public attention has recently focused on creating a honey source to produce eco-friendly, high-quality honey by reducing industrial pollutants and securing a honey source through environmental protection. As one of these methods, small-scale beekeeping is being carried out using the space of rooftops or buildings based on the honey source created in the city center by the government support for urban beekeeping. However, the honey produced in these beekeeping industries is limited to environmentally friendly honey production due to pollution of the urban air environment, and damage caused by attacks by bees is not an alternative. Therefore, to stably produce eco-friendly honey without heavy metal contamination from changes in the global environment, it is imperative to create an abundant honey source and develop eco-friendly and durable beekeeping materials (Sharma et al., 2014). Comb foundations are the base material for nesting the beehive, which is the core of beekeeping materials currently used; it primarily uses beeswax, a secretion of bees, and synthetic paraffin wax and beeswax to reduce costs to the increase in the price of beeswax. Paraffin comb foundation molded by mixing beeswax and paraffin wax for a particular use (Semkiw and Skubida, 2013; Svečnjak et al., 2019) is easy to manufacture and has an affinity with bees, so it has the advantage of a high nesting rate within a short time. However, they are in the form of low-molecular waxes and have weak mechanical properties that result in breakage during honey extraction and weak durability, so it is not easy to use repeatedly. In addition, it is challenging to dispose of waste after use, and the occurrence of pests in bees is serious, so the development of new comb foundations to replace them is urgently needed (Seeley et al., 2005). It was developed to replace the honeycomb foundation of beeswax in the United States, Germany, etc. It is a polymer material that produces a plastic comb foundation in a shape similar to a wax comb. However, these foundations are closed, have a low nesting rate, and are more expensive than beeswax comb foundations (Abdelrazeq et al., 2019). In Korea, An open plastic comb foundation in which honeycomb-shaped hexagons intersect was developed using polycarbonate (PC) resin, which indicated a low nesting rate but excellent durability. These plastic honeycomb bases are durable, can be used repeatedly, have excellent honey extractability, and can be mass-produced. The honeycomb base is produced by extruding a pattern similar to the beeswax foundation currently used in the beekeeping industry, but there is a limit to using it in countries with a shortage of honey sources and a short flowering period (Zhang et al., 2011). Over the past 20 years, the technology of comb foundation has changed markedly, expanding the types of foundation available to beekeepers so that under favorable conditions, the bees can build honeycombs on plastic foundations (Mohr and Doyoyo, 2004; Goswami, 2006).

MATERIALS AND METHODS

1. Improvement of honeycomb foundation materials

It is crucial first to understand bees’ physiology to produce plastic comb foundation friendly to bees. The bee’s nesting environment has compassionate characteristics to temperature, color, shape, and smell of comb foundation (Harrap et al., 2017). Plastic comb foundations currently used in the United States and China are not penetrated on both sides, so the temperature transfer power is low, which lowers the nesting rate, so it is not suitable for use in Korea (Xie et al., 2018). In order to improve these shortcomings, a domestic company has manufactured and supplied clean comb foundations in the form of gripping honeycomb structures by injection molding polycarbonate (PC) material. However, these materials are expensive and coated with beeswax on the surface to increase the nesting rate, and also there are several inherent problems in using them in an environment where there is a shortage of honey sources and a short flowering period in Korea. In addition, materials other than PC were used to increase price competitiveness, but problems of the smell and deformation due to the plastic additives occurred, so the usage is shallow except for some farms (Balla et al., 2019). Recently, to improve these disadvantages, research has been carried out on the development and commercialization of bee-friendly plastic honeycomb with excellent durability and high nesting rate by adding beefriendly additives to general purpose resins and modifying the structure. Therefore, compared to beeswax comb foundations, most imported from China, plastic honeycomb plates are more cost-effective and durable to be used for an extended period.

2. Characteristics of beeswax and plastic materials for comb foundation

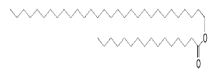

Beeswax, as a sticky amorphous substance, is a solid animal wax obtained by hot pressing or solvent extraction, and Its main constituents are palmitate, palmitoleate, and oleate esters of long-chain aliphatic alcohols, with the ratio of triacontanyl palmitate to cerotic acid, the two principal constituents, being 6 : 1. Furthermore, it contains various fatty acids, alcohols, and higher hydrocarbons. Polyolefin (polypropylene, PP; high-density polyethylene, HDPE) resin, a plastic, has slightly lower impact resistance and transparency than polycarbonate but is much cheaper and highly recyclable, so it is environmentally friendly. As a polymer, it is characterized by non-toxicity, chemical stability, and moldability and has good strength and heat resistance, making it a very suitable material as a plastic comb foundation. In Table 1, the chemical structure and physical properties of polypropylene, a plastic material, and natural beeswax, an existing honeycomb material, are compared (Abdikheibari et al., 2015).

3. Kneading and molding of compounding composition

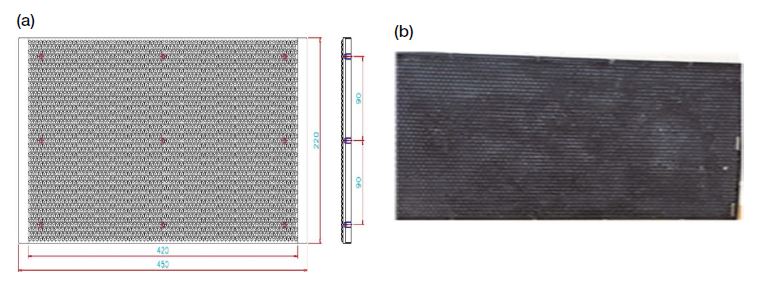

The kneading of raw materials from the compounding device can be performed effectively (Tascioglu et al., 2016). When the material is kneaded in a temperature range of 250 to 290℃, the chemical change of the composition can be prevented in advance, and the composition is uniformly blended. The kneading step may be performed for 5 to 30 min, but there is no limitation in the case where the composition can be uniformly kneaded, and the forming step is a process of forming a honey comb structure from the compounding dough through extrusion. A small amount of beeswax may be added to ensure adhesion when putting the dough into the molding machine. Fig. 1 shows the shape of the plastic comb foundation coated with beeswax. In general, bees are susceptible to smell and temperature, so a beeswax coating step may be added to improve further the eco-friendliness of the produced comb foundation and the nesting ability of bees. Considering the price of cheap paraffin wax and more expensive beeswax, the composition of 8 : 2 is effective for honeycomb coating materials, and the surface coating of molded comb foundation is generally performed by spraying or dipping method.

RESULTS AND DISCUSSION

1. Composition of primary raw materials for compounding

The compounding composition for honeycomb-structured plastic comb foundations with high durability, dimensional stability, and easy molding processability is formulated with 70-80 wt% of homopolypropylene (or high-density polyethylene) and 5-20 wt% of beeswax and wood flour in the range of 5-10 wt%, in addition to organic additives such as antioxidants, heat stabilizers, and compatibilizers, inorganic additives such as talc to improve strength and processability, and especially beefriendly and harmless yellow of colorants can be included together. Table 2 shows the composition of the primary raw material for manufacturing the plastic comb foundation. When beeswax, which is the secretion of bees collected from the beehive, is added to the compounding composition, affinity for bees is ensured, and there is no rejection in the nesting process. Due to these advantages, it is possible to secure the beeswax coating effect without going through a separate process of coating the beeswax during the production of comb foundation, thereby significantly lowering the production cost of the foundation. It is differentiated from the conventional manufacturing method, which usually undergoes a process of coating beeswax. Including beeswax in the compounding composition can exhibit high dimensional stability while having a nesting rate suitable for a honey comb. Beeswax may be included in about 5-20 wt% in the compounding.

When beeswax is added in a more significant amount than this range, the dimensional stability of the beeswax is impaired. When it is added less than that, it is not easy to guarantee the nesting rate of comb foundation. Wood flour may be a by-product generated during building materials using wood. However, specifically, it is a finely pulverized product after drying at least one of pine, ginkgo, juniper, arborvitae, cinnamon, and cypress, and the size of the pulverized particles is usually in the range of 0.05 to 1.0 mm. When a comb foundation is prepared with a composition containing such wood powder, it is possible to preserve wood texture during use and increase mechanical strength. comb foundation. Wood flour may be a by-product generated during building materials using wood. However, specifically, it is a finely pulverized product after drying at least one of pine, ginkgo, juniper, arborvitae, cinnamon, and cypress, and the size of the pulverized particles is usually in the range of 0.05 to 1.0 mm. When a comb foundation is prepared with a composition containing such wood powder, it is possible to preserve wood texture during use and increase mechanical strength. In particular, since wood has a characteristic temperature control function, it environmentally and in a bee-friendly manner increases the nesting rate. Since the compounding composition for comb foundation includes beeswax and wood flour simultaneously, the lubricity of beeswax improves the dispersibility of the wood flour so that it shows a homogeneous mixing ratio even in a large area. If the sum of the additional amounts of beeswax and wood flour is less than the range of 10-30 wt%, a homogeneous composition of the comb foundation cannot be expected. If it is more significant than this range, it is challenging to promote the durability of the foundation. Therefore, when the sum of the weights of beeswax and wood flour is within an appropriate range, the produced comb foundation has high dimensional stability, is easy to process, and has the advantage of lowering the production cost.

2. Characterization of polypropylene compound

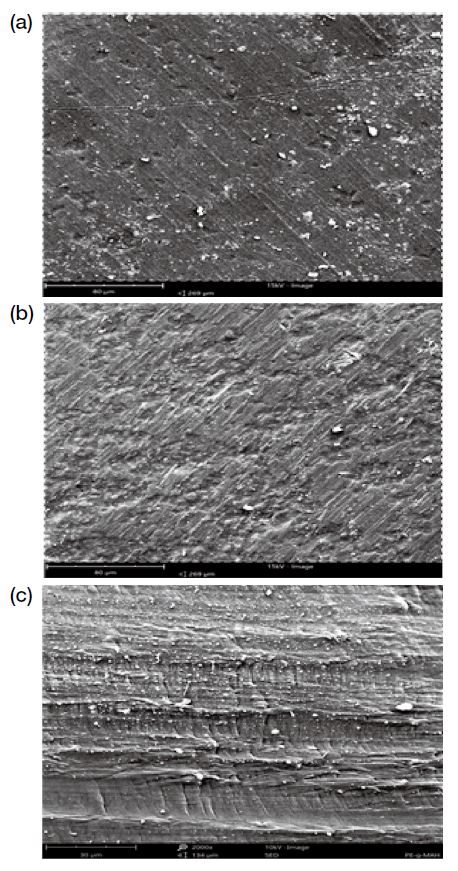

Raw materials with a primary composition made from polypropylene resin were compounded, and this compounding material was molded into a test piece of a specific size through an extruder and then dip-coated with beeswax. Fig. 2(a) and 2(b) are the results of morphology analysis using a scanning electron microscope (SEM) for the PP compound specimens before and after beeswax coating, respectively. In Fig. 2(a), the compound specimen has a smooth surface. The surface of the coated specimen in 2(b) also shows a similar state, but it has a bit rough, which can be increasing the cohesiveness, more accessible to produce honey. It can be expected that the thickness of the coated beeswax will be uniform. Fig. 2(c) is a photograph of the fracture surface of the beeswax-coated specimen. The cross-section exhibits good adhesion of the beeswax layer on the composite substrate.

Morphology of polypropylene compound specimens for honeycomb foundation. (a) uncoated fresh surface, (b) beeswaxcoated surface, and (c) cross-section after beeswax coating.

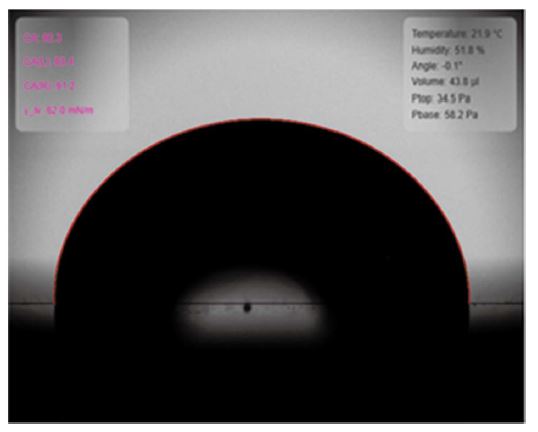

The degree of adhesion between two materials is qualitatively considered with the phase contact angle through wettability, and a contact angle of 90° or less in the solid-liquid phase generally indicates good wetting (Style et al., 2021). Fig. 3 shows the shape of a drop of molten beeswax placed on a PP compound specimen. In Fig. 3, the contact angle of the beeswax liquid phase to the composite substrate indicates 92°, and this relatively high angle value is mainly due to the hydrophobicity of beeswax.

3. Effects of additives on polypropylene compound properties

It is possible to further include lignin in the compounding composition for comb foundation, and it is mixed in a small amount so as not to affect the durability of the comb foundation. Lignin is an organic compound extracted from wood (Sannigrahi et al., 2010) and can also be obtained from the residue remaining after terpene oil is extracted in the pulp and paper processing process using wood. When preparing a honeycomb foundation with a compounding composition containing 5-8 wt% of lignin, it is possible to realize color and improve the texture of wood in the comb foundation. That is, by binding the incorporated lignin with the wood flour, the wood texture of the produced foundation is strengthened, and thus, the suitability for use as an environmentally friendly and bee-friendly comb foundation is further increased. Lignin may be mixed in the compounding composition to 1 to 12 wt%, and when included in more than this range, the durability of the prepared foundation will fall.

An inorganic additive having a deodorizing function may include 1 to 5 wt% in the compounding composition for comb foundation. The deodorizing additives are similar to honeycomb structural materials used for various filters or catalyst carriers (Avila et al., 2005) containing talc, activated carbon, elvan, zeolite, active alumina. Moreover, these additives combine with the beeswax and wood powder contained in the compounding composition for comb foundation through heating and kneading. The produced comb foundation can be prevented from dislodging and being lost when a physical impact is applied. Talc, activated carbon, elvan, zeolite, activated alumina, etc., constituting the additive, are powdered with a 0.1 to 1.0 mm particle diameter. However, the size is usually acceptable up to 3.0 mm, and the average diameter of pores formed in the powder is about 0.3 to 1.5 μm. Therefore, when such a ceramic powder additive is included in the range of 1 to 5 wt% in the compounding composition, it is possible to prevent the deterioration of mechanical properties of the comb foundation to be manufactured while ensuring the deodorizing effect.

The polyprophylene resin was compounded with additives of 10 wt% of talc as a filler, 5 wt% of bamboo as a wood flour, 3 phr of maleic anhydride as a compatibilizer and 2 phr of carbon black as a black masterbatch to be applied to the plastic comb foundations. Table 3 shows the mechanical properties of the polypropylene compound moldings compared to those of a general homopolypropylene. The property values may be the performance criteria of the plastic materials for the honeycomb foundation.

CONCLUSION

Examining the current status of comb foundations for a beehive in detail, it becomes clear that we need to use semipermanent plastic comb foundations. A polyolefin resin was selected as a polymer material suitable for producing honeycomb foundations with affinity with bees and a high nesting rate. A wax coating method on the surface of the molded composite foundation was proposed to improve the nesting of bees further; in this case, the coating of beeswax on the polypropylene composite showed good adhesion. The plastic comb foundation obtained from the compounding composition is recyclable. It has excellent durability, prevents environmental pollution caused by the existing disposable wax foundations, and can significantly contribute to the practicality and economic feasibility of the eco-friendly beekeeping industry.

Acknowledgments

This research was carried out with the support of the Rural Development Administration’s Agricultural Support Technology Development Project (Project No. PJ016263).

References

-

Abdelrazeq, H., P. Sobolčiak, M. Al-Ali Al-Maadeed, M. Ouederni and I. Krupa. 2019. Recycled polyethylene/paraffinwax/expanded graphite-based heat absorbers for thermal energy storage: an artificial aging study. Molecules 24(7): 1217.

[https://doi.org/10.3390/molecules24071217]

-

Abdikheibari, S., R. Parvizi, M. H. Moayed, S. M. Zebarjad and S. A. Sajjadi. 2015. Beeswax-colophony blend: A novel green organic coating for protection of steel drinking water storage tanks. Metals 5(3): 1645-1664.

[https://doi.org/10.3390/met5031645]

- Al Naggar, Y. A., E. S. A. Naiem, A. I. Seif and M. H. Mona. 2013. Honey bees and their products are bio-indicators of environmental pollution with heavy metals. Mellifera 13: 1-20.

-

Avila, P., M. Montes and E. E. Miró. 2005. Monolithic reactors for environmental applications: A review on preparation technologies. Chem. Eng. J. 109(1-3): 11-36.

[https://doi.org/10.1016/j.cej.2005.02.025]

-

Balla, V. K., K. H. Kate, J. Satyavolu, P. Singh and J. G. D. Tadimeti. 2019. Additive manufacturing of natural fiber reinforced polymer composites: Processing and prospects. Compos. B. Eng. 174: 106956.

[https://doi.org/10.1016/j.compositesb.2019.106956]

- Celli, G. and B. Maccagnani. 2003. Honey bees as bioindicators of environmental pollution. Bull. Insectology 56 (1): 137-139.

-

Goswami, S. 2006. On the prediction of effective material properties of cellular hexagonal honeycomb core. J. Reinf. Plast. Compos. 25(4): 393-405.

[https://doi.org/10.1177/0731684405060567]

-

Harrap, M. J., S. A. Rands, N. H. de Ibarra and H. M. Whitney. 2017. The diversity of floral temperature patterns and their use by pollinators. Elife 6: e31262.

[https://doi.org/10.7554/eLife.31262]

-

Mohr, D. and M. Doyoyo. 2004. Experimental investigation on the plasticity of hexagonal aluminum honeycomb under multiaxial loading. J. Appl. Mech. 71(3): 375-385.

[https://doi.org/10.1115/1.1683715]

-

Sannigrahi, P., A. J. Ragauskas and S. J. Miller. 2010. Lignin structural modifications resulting from ethanol organosolv treatment of loblolly pine. Energy & Fuels 24(1): 683-689.

[https://doi.org/10.1021/ef900845t]

-

Seeley, T. D., A. M. Reich and J. Tautz. 2005. Does plastic comb foundation hinder waggle dance communication? Apidologie 36(4): 513-521.

[https://doi.org/10.1051/apido:2005037]

-

Semkiw, P. and P. Skubida. 2013. Comb construction and brood development on beeswax foundation adulterated with paraffin. J. Apic. Sci. 57(1): 75-83.

[https://doi.org/10.2478/jas-2013-0009]

-

Sharma, D., D. P. Abrol, H. Ahmad, R. S. Bandral and A. Ishar. 2014. Traditional Beekeeping In Jammu And Kashmir, India. Bee World 91(3): 62-64.

[https://doi.org/10.1080/0005772X.2014.11417605]

-

Style, R. W., R. Tutika, J. Y. Kim and M. D. Bartlett. 2021. Solid-liquid composites for soft multifunctional materials. Adv. Funct. Mater. 31(1): 2005804.

[https://doi.org/10.1002/adfm.202005804]

-

Svečnjak, L., O. Jović, S. Prđun, J. Rogina, Z. Marijanović, J. Car, M. Matošević and I. Jerković. 2019. Influence of beeswax adulteration with paraffin on the composition and quality of honey determined by physicochemical analyses, 1H NMR, FTIR-ATR, and HS-SPME/GC-MS. Food Chem. 291: 187-198.

[https://doi.org/10.1016/j.foodchem.2019.03.151]

-

Tascioglu, C., M. Tufan, M. Yalcin and S. Sen. 2016. Determination of biological performance, dimensional stability, mechanical and thermal properties of wood-plastic composites produced from recycled chromated copper arsenate treated wood. J. Thermoplast. Compos. Mater. 29(11): 1461-1479.

[https://doi.org/10.1177/0892705714565704]

-

Xie, W. H., S. H. Meng, L. Ding, H. Jin, S. Y. Du, G. K. Han, L. B. Wang, C.H. Xu, F. Scarpa and R. Q. Chi. 2018. High-temperature, high-velocity impact on honeycomb sandwich panels. Compos. B. Eng. 138: 1-11.

[https://doi.org/10.1016/j.compositesb.2017.06.022]

-

Zhang, Z., S. Liu and Z. Tang. 2011. Comparisons of honeycomb sandwich and foam-filled cylindrical columns under axial crushing loads. Thin-Walled Struct. 49(9): 1071-1079.

[https://doi.org/10.1016/j.tws.2011.03.017]