A Study on the Sorting Method for the Drone Pupae (Apis mellifera L.)

Abstract

This study introduces a current method for sorting drone pupae with the aim of addressing its limitations by designing a specialized drone pupae frame. The sorting of drone pupae was categorized into three primary stages, further subdivided into nine steps. This division of sorting stages was necessitated by the limited time available for sorting at room temperature. The design of the dedicated drone pupae frame was developed to enhance the existing sorting method. Nevertheless, additional research is required for practical field implementation. Consequently, it is expected that the findings of this study will enable many beekeeping households to directly sort drone pupae. The refinement of sorting methods is deemed crucial and will necessitate further research.

Keywords:

Drone pupae, Sorting, Food materialsINTRODUCTION

Honeybees are considered livestock, similar to cattle, horses, and sheep, and beekeeping products obtained from honeybees are defined as livestock products (MAFRA, 2022). The domestic beekeeping industry in South Korea is highly dependent on honey production, which accounts for 53.7% of the total production value, with honey generating 1,228 billion KRW out of the total 2,288 billion KRW (Lee et al., 2019). However, this reliance on honey leaves the industry vulnerable to fluctuations caused by climate change and outbreaks of pests and diseases. When honey production is affected, it directly leads to a decrease in income for beekeeping households (Lee et al., 2019). Consequently, there is a need for diversifying income sources beyond honey production.

The drone pupae underwent characterization, nutritional evaluation, and toxicity assessment by the Rural Development Administration in 2020 (MFDS, 2020). Based on these evaluations, it was officially recognized as an edible insect by the Ministry of Food and Drug Safety (MFDS). As of October 2023, the MFDS has approved a total of 10 edible insects for use as food ingredients, which include silkworm pupa (Bombyx mori L.), along with honeybees, crickets, white-spotted flower chafers, brown white-spotted flower chafers, longhorned grasshoppers, double-spined carrion beetles, American giant water bugs (extract), and mole crickets.

According to a study by Kim et al. (2018a), drone pupae is considered a highly nutritious insect due to its high protein content, as well as various carbohydrates, fats, amino acids, minerals, and vitamins. Recent research has actively explored the functional properties of drone pupae, such as its antioxidant effects, anti-inflammatory activities (Kim et al., 2019a), blood glucose regulation (Kim et al., 2020), hair loss improvement (Kim et al., 2020a), protein characteristics related to drone pupae hydrolysis (Kim et al., 2020b), anti-diabetic activity (Pyo et al., 2020), Anti-proliferative effect on HepG2 cell line (Kim et al., 2022a) and cytokine profile in human skin keratinocytes (Kim et al., 2023). Drone pupae offers the advantage of easy and cost effective production for beekeeping households, making it an emerging source of income. However, the lack of established methods for the sorting of drone pupae presents challenges for many beekeeping households.

Therefore, this research analyzed the characteristics of drone pupae to assess the sorting method and, furthermore, aimed to utilize the fundamental data for implementing drone pupae sorting in beekeeping households.

MATERIALS AND METHODS

1. Sample

Drone pupae (17-23 days old) were produced in 2023 by beekeeping households in Dangjin, Chungcheongnam-do, South Korea. All storage and transportation processes were maintained at temperatures below -20℃.

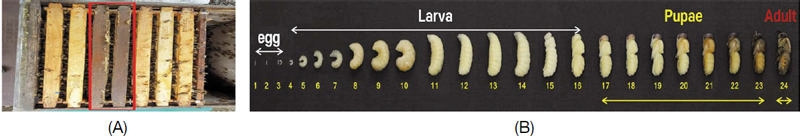

2. Production of drone pupae

To produce drone puae, drone frame was inserted at the 3rd to 4th location in a normal beehive. After oviposition of the queen bee and collected the drone frame at 17-23 days of age. The collected drone frame was immediately stored at below -20°C.

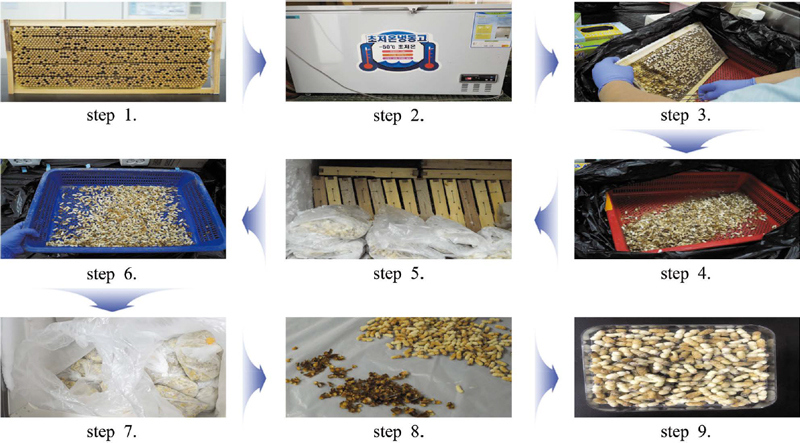

3. Drone pupae sorting

The process of sorting drone pupae involved using scrapers (head 50×100 mm), rectangular plastic trays (58.6×43.7×11.3 cm), and rectangular stainless steel trays (34.5×21.5×1.2 cm). Initially, the drone pupae were stored in a frozen state (below -20℃) for over 12 hours. Then, the frozen drone pupae were scraped on the rectangular trays using scrapers. The broken wax and drone pupae were separated in the first step and stored in the cold. Subsequently, the stored samples were taken out and resorted in the second step. Finally, pure drone pupae were sorted in the third step using stainless steel trays.

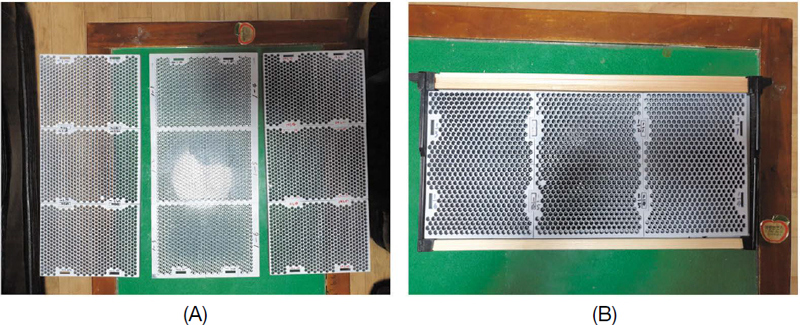

4. Design

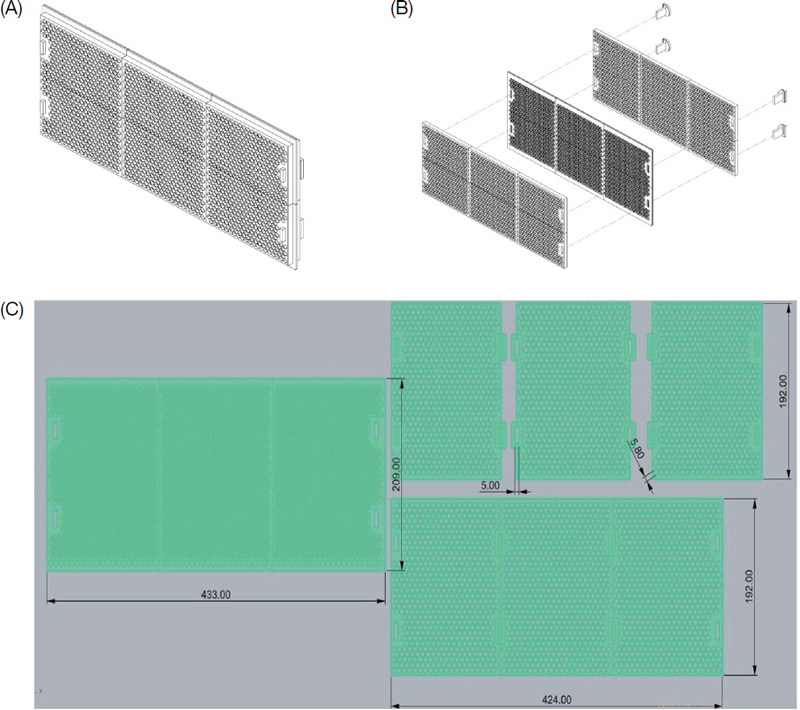

In order to improve the sorting method of drone pupae, a specialized drone pupae tray was designed (Kim et al., 2022b). This design consists of two inner panels and two outer panels that connect via a socket, as illustrated in Fig. 2A, showcasing the overall structure. Fig. 2B provides a disassembled view of the design, while Fig. 2C presents the complete blueprint of the specialized drone pupae tray design.

Drone pupae frame design (A), disassembled view of the drone pupae frame (B), and blueprint of the drone pupae frame design (C).

The difference from the conventional frame, its design which facilitates the collection of drone pupae by combining three panels.

RESULTS AND DISCUSSION

Drone pupae (in its original state) contains over 80% moisture, necessitating the maintenance of a frozen state from production through the sorting and distribution stages. Maintaining a frozen state during the sorting process is crucial; without it, the pupae lose their form, making sorting a challenging task. In this study, we maintained a frozen state throughout the drone pupae production, transportation, and sorting phases. The sorting process, as shown in Fig. 3, employed readily available tools such as trays, spatulas, and scrapers, suitable even for home use. A critical aspect of the sorting process was the continuous maintenance of the frozen state of the drone pupae. The sorting process was divided into three major steps. The first step involved stages 1 to 5, where we sorted one batch of pupae. The second step encompassed stages 5 to 7, where we retrieved the samples from frozen storage for a secondary sorting. The final step, stages 7 to 9, completed the ultimate sorting. Recently, drone pupae have transitioned from being a temporary food ingredient to a regular food source, placing increased importance on raw material quality control. According to Kim et al. (2019b), the peroxide value and acid value of freeze-dried drone pupae powder are within the standards and specifications set for processed food products derived from insects by the Food Code. These values are 2.92±0.28 mg/g and 1.94±0.26 meq/kg, respectively. In contrast, honeybees are known to use propolis collected from plants to fill gaps in honeycombs and maintain the honeycomb in a sterile state, and food-poisoning bacterial and fungal toxins were not detected in drone pupae collected from honeycombs as reported previously (Ghisalberti, 1979; Kim et al., 2018b). This suggests that drone pupae have suitable oxidative stability and sanitary safety for use as a food ingredient. Therefore, for diversifying the use of drone pupae in the food industry and as a new income source for beekeeping households, the management of sorting processes is deemed crucial.

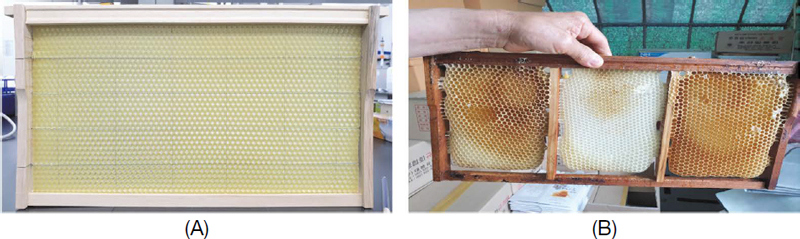

The raw materials required for drone pupae production involve using commercially available drone pupae frame (Fig. 4A) or modifying drone pupae frame directly within the farming households (Fig. 4B). According to Choi et al. (2009), drone pupae harvested from drone pupae frame designed for drone pupae production displayed a yield rate of approximately 92.8% for honey-rich period and about 93.0% for nonhoney period, showing uniform and consistent production. However, there is currently no reported information available on a drone pupae frame specifically designed for sorting.

Therefore, we aimed to develop a suitable egg tray for sorting drone pupae and performed its design and construction, as depicted in Fig. 5. The design involves the assembly of one inner panel and two outer panels through sockets, with the primary purpose of sealing individual workerbee in their wax cells. This design is anticipated to maintain the original form of the drone pupae (in its original state) and reduce sorting time compared to conventional methods. However, additional research is deemed necessary for practical application in the field.

CONCLUSION

This study aims to present a current method for sorting drone pupae while addressing its shortcomings, by designing a dedicated drone pupae frame. The process of sorting drone pupae was divided into three main stages, further detailed into nine steps. This division of sorting stages was necessary due to the limited time available for sorting at room temperature (If working in a space where -20℃ can be maintained, the entire sorting process could be completed at once, although caution is required for worker safety). The design of the specialized drone pupae frame was developed to improve the existing sorting method. However, it requires additional research for practical application in the field.

Beekeeping is a type of agricultural venture that allows for low capital startup, making it a preferred choice for family businesses and individuals returning to farming. As a result, it is believed that the findings of this study will enable many beekeeping households to directly sort drone pupae. The enhancement of sorting methods should be considered essential and will require further research.

Acknowledgments

This study was supported by the Joint Research Project of the Rural Development Administration (Project No. RS-2021-RD009014) of the Republic of Korea.

References

- Choi, Y. S., J. H. Yeo, S. O. Woo, M. L. Lee, M. Y. Lee, K. G. Lee, B. R. Jin and H. K. Kim. 2009. Base of beehive for drone production. 10-2009-0006276.

-

Ghisalberti, E. L. 1979. Propolis: a review. Bee World 60: 59-84.

[https://doi.org/10.1080/0005772X.1979.11097738]

-

Kim, S. G., S. O. Woo, K. W. Bang, H. R. Jang and S. M. Han. 2018a. Chemical composition of drone pupa of Apis mellifera and its nutritional evaluation. J. Apic. 33(1): 17-23.

[https://doi.org/10.17519/apiculture.2018.04.33.1.17]

-

Kim, S. G., S. O. Woo, H. R. Jang, H. M. Choi, H. J. Moon and S. M. Han. 2018b. Safety investigation on foodborne pathogens and mycotoxins in honeybee drone pupas. J. Food Hyg. Saf. 33(5): 399-403.

[https://doi.org/10.13103/JFHS.2018.33.5.399]

-

Kim, H. Y., S. O. Woo, S. G. Kim, K. W. Bang, H. M. Choi, H. J. Moon and S. M. Han. 2019a. Anti-inflammatory activities of drone pupae (Apis mellifera L.) in macrophages. J. Apic. 34(3): 255-259.

[https://doi.org/10.17519/apiculture.2019.09.34.3.255]

-

Kim, H. Y., S. O. Woo, S. G. Kim, K. W. Bang, H. M. Choi, H. J. Moon and S. M. Han. 2019b. Analysis of oxidative stability in drone pupae (Apis mellifera L.). J. Apic. 34(1): 63-66.

[https://doi.org/10.17519/apiculture.2019.04.34.1.63]

-

Kim, H. Y., S. O. Woo, S. G. Kim, H. M. Choi, H. J. Moon and S. M. Han. 2020. Antioxidant and antihyperglycemic effects of honeybee drone pupae (Apis mellifera L.) extracts. J. Apic. 35(1): 33-39.

[https://doi.org/10.17519/apiculture.2020.04.35.1.33]

-

Kim, J. E., D. I. Kim, H. Y. Koo, H. J. Kim, S. Y. Kim, Y. B. Lee, J. H. Moon and Y. S. Choi. 2020a. Evaluation of honeybee (Apis mellifera L.) drone pupa extracts on the improvement of hair loss. J. Apic. 35(3): 179-188.

[https://doi.org/10.17519/apiculture.2020.09.35.3.179]

-

Kim, J. E., D. I. Kim, H. J. Kim, S. Y. Kim, Y. B. Lee, J. H Moon, H. G. Park and Y. S. Choi. 2020b. Characteristics of hydrolysis of protein in drone pupa (Apis mellifera L.). J. Apic. 35(3): 169-177.

[https://doi.org/10.17519/apiculture.2020.09.35.3.169]

-

Kim, S. M., S. G. Kim, S. O. Woo, H. Y. Kim, H. M. Choi, H. J. Moon and S. M. Han. 2022a. Antiproliferative effect of drone pupa (Apis mellifera L.) extract on human hepatocellular carcinoma (HepG2) cell line. J. Apic. 37(3): 235-241.

[https://doi.org/10.17519/apiculture.2022.09.37.3.235]

- Kim, H. Y., S. M. Han, S. G. Kim, H. M. Choi, S. M. Kim, H. J. Han, K. S. Han and Y. S. Kwon. 2022b. Base Frame for beekeeping. 30-2022-0050499.

-

Kim, S. M., S. G. Kim, S. O. Woo, H. Y. Kim, H. M. Choi, S. K. Kim, H. J. Lee, H. J. Moon, Y. S. Lee, S. Ryu and S. M. Han. 2023. Cytokine profile in human skin keratinocytes exposed to drone (Apis mellifera L.) fat extract against inflammation. J. Apic. 38(1): 59-67.

[https://doi.org/10.17519/apiculture.2023.04.38.1.59]

- Lee, J. M., Y. L. Kim, C. H. Kim and S. H. Woo. 2019. https://repository.krei.re.kr/handle/2018.oak/23415, . Korea Rural Economic Institute.

- MAFRA (Ministry of Agriculture, Food and Rural Affairs). 2022. Livestock industry act. Article 2 (Definitions).

- MFDS (Ministry of Food and Drug Safety). 2020. https://www.nifds.go.kr/brd/m_21/view.do?seq=12827

-

Pyo, S. J., C. E. Jung and H. Y. Sohn. 2020. Platelet aggregatory and antidiabetic activities of larvae, pupae, and adult of honeybee drone (Apis mellifera). J. Apic. 35(1): 41-48.

[https://doi.org/10.17519/apiculture.2020.04.35.1.41]