Analysis of the Physicochemical Properties of Beeswax of Apis mellifera Linnaeus and Apis cerana Fabricius

Abstract

To evaluate the physicochemical properties of beeswax produced by Apis mellifera Linnaeus (Am) and Apis cerana Fabricius (Ac), we collected and extracted pure beeswax from a bee hive. Detailed analysis of the physicochemical properties was then performed at the Korean Health Supplement Institute. We tested eight characteristics of the beeswax, including the levels of lead, arsenic, and mercury; melting point; acid value; saponification value; esterification value; and peroxide value of both Am and Ac beeswax. The levels of all heavy metals were below safety values, and melting points at 64.5°C were the same for the two beeswax samples. The esterification value of Ac beeswax (79.94) was higher than that of Am beeswax (73.73). However, the saponification, peroxide, and acid values of Am beeswax were higher than those of Ac beeswax. The saponification values for Ac and Am beeswax were 87.41 and 95.44, respectively. Notably, there was a significant difference in peroxide values and acid values between Ac and Am beeswax. The acid value and peroxide value of Am beeswax were more than 3-times and 45-times higher, respectively. Based on these results, beeswax can safely be used as a food additive.

Keywords:

Beeswax, Apis mellifera, Apis cerana, Physicochemical propertiesINTRODUCTION

Although there are several insects that naturally produce wax. In particular, Apis mellifera Linnaeus (Am) and Apis cerana Fabricius (Ac) produce the most beeswax, which is then developed into products with the most uses (Kaluza et al., 2016). Beeswax is secreted in liquid form by special wax glands in the abdomen of the bee and solidifies on contact with air (Chauvin, 1968; Bogdanov, 2004). Pure beeswax is almost white when secreted by bees, but when mixed with honey and pollen it takes on a yellow tint, and after a few years it becomes brown because it contains cocoons (Hepburn et al., 1991). Beeswax chemically consists of over 300 compounds, predominantly fatty acid esters (67%), hydrocarbons (14%) and free fatty acids (13%) as a complex mixture (Tulloch, 1980).

The composition of beeswax is related to both the genetic factors of the bee and the materials collected by the bees. Therefore, the composition of the beeswax may vary between bee species, but there is generally no significant difference in the basic chemical composition. However, there is a small difference related to the ratio of major compounds (Fröhlich et al., 2000; Buchwar et al., 2006). Beeswax has been documented as a medicinal product since ancient Egypt. Amcording to papyrus records (1,550 B.C.), it was used as a material to treat burns and wounds, and to relieve articulation pain. Further, records from ancient Rome that beeswax was applied similarly (Chauvin, 1968). It is also one of the first cosmetic ingredients created by the Greek physician Galen in 150 B.C. consisted of beeswax (Stacey, 2001). In recent years, the importance of the antibacterial activity of bee products has emerged and been studied, but unlike other bee products, beeswax has only been recently studied. Beeswax exhibits antibacterial activity against several bacterial species and Candida albicans yeast. It was particularly effective against Gram-positive bacteria, such as Staphylococcus aureus, Streptococcus pyogenes, and also against some Gram-negative bacteria, such as Escherichia coli (Ghanem, 2011). In recent years, the use of beeswax mixed with other bee products has proven effective in treating atopic dermatitis, psoriasis, and diaper dermatitis (Al-Waili, 2005; Lewis et al., 2012). All treated patients showed significant improvement after administration and were found to be more effective than conventionally used drug treatments. Significant effects were also demonstrated not only for dermatitis but also for hemorrhoids and anal-related diseases (Al-Waili et al., 2006). It has also been reported to be effective for anti-inflammatory activity (Carbajal et al., 1998), gastrointestinal mucosal protection (Carbajal et al., 2000), and gastroesophageal reflux (Zamora et al., 2014). Currently, beeswax is used for cosmetics, pharmaceuticals, candles, and other uses (Dumitru et al., 2022). Moreover, it is often used as a pigment carrier in food technology and as a food preservative. It is also used in drug and pill coatings owing to low allergenicity. Therefore, in this study, we analyze the composition of local Korean Am beeswax and Ac beeswax, which is produced for research on various functional materials of beeswax, as well as for food additives. Without research on the physical and chemical properties of beeswax, the development and processing of biological materials and the scope of its use as a food additive can be expanded.

MATERIALS AND METHODS

1. Beeswax extraction

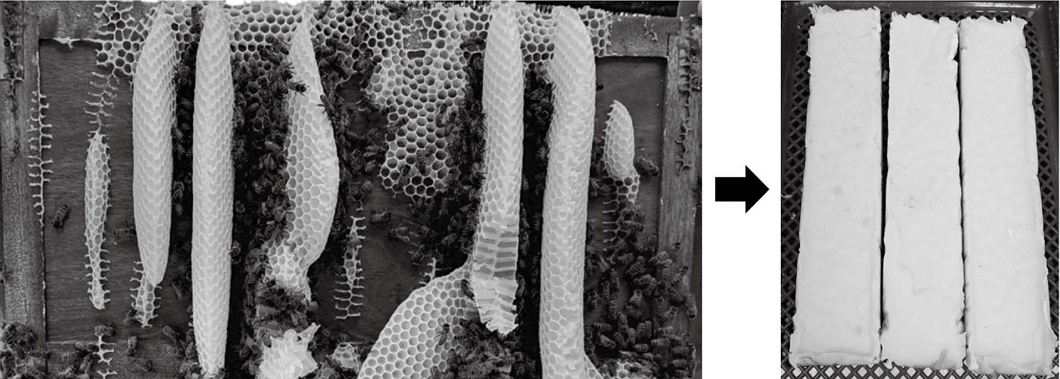

The harvesting of beeswax for the analysis took 4 months, from April, 2021 to early August, 2021 in Wanju, South Korea. Beeswax collected from Am and Ac was compacted and prepared for composition analysis after pure beeswax extraction (Fig. 1).

2. Extraction of Am and Ac beeswax

Beeswax from both species (Am and Ac) was stored separately to keep the samples from mixing. Next, the samples were placed in a beeswax melting steam machine (Korea Beekeeping Agricultural Cooperative) and heated with steam at 50℃. for 2 h to extract the pure beeswax.

3. Compositional analysis of beeswax

To analyze the composition of Am and Ac beeswax, we commissioned Korea Functional Food Research Institute to conduct a detailed test analysis. A total of eight analysis items were requested: levels of arsenic, lead, and mercury, as well as the melting point, acid value, esterification value, saponification value, and peroxide value. The method was based on the test method corresponding to each item of (a) Food additives and beeswax purity test in Food Additives and Mixed Preparations 4 Item Standards and Standards for Food Additives, excluding mercury. Mercury testing was performed based on the Mercury Test Method of the 5th General Test Method for Additive Revolution. All experiments was repeated 3-times.

Arsenic was measured using an inductively coupled plasma (ICP) after preparing a sample by placing 0.5 g of the sample into a microwave digestion system, treating it with nitric acid, and decomposing it.

A 1 g sample of lead was taken, dried and carbonized, and then painted at 450-550℃. After painting, the residue was moistened with water, after which 2-4 mL of hydrochloric acid was added and evaporated until dry. Next, 0.5 N nitric acid was added and dissolved by heating, and then the insoluble matter was filtered. After adding 0.5 N nitric acid to this mixture to prepare a test solution, it was analyzed by ICP. For mercury, a 0.03 g sample quantified with a mercury analyzer.

The melting point was measured using a melting point measuring instrument. The acid value was measured by placing 3 g of the sample in a 200 mL Erlenmeyer flask, adding 25 mL of anhydrous alcohol neutralized with potassium hydroxide reagent using phenolphthalein reagent as an indicator, until the sample dissolves. As a test solution, the liquid heated to 100℃ was tested according to the acid value of the oil flow test method.

To determine the esterification value, 25 mL of 0.5 N alcoholic potassium hydroxide solution and 50 mL of alcohol was added to the solution for which the acid value has been measured. Next, a reflux condenser was attached, heated on a water bath for 4 h, and excess alkali was removed with 0.5 N hydrochloric acid, which was titrated to obtain the ester content.

The saponification value was determined by weighing 5 g of the sample, adding 50 mL of 0.5 N alcoholic potassium hydroxide solution, and attaching the reflux condenser. This was inspected for 1 h and tested according to the saponification value in the oil flow test method.

The peroxide value was determined by weighing 5 g of sample, adding 35 mL of acetic acid:chloroform (3 : 2) solution and dissolving it until transparent, and then adding nitrogen to sufficiently replace the air in the container. Next, 1 mL of the potassium iodine reagent was added while removing the nitrogen gas, plugging the tube, shaking and mixing for 1 min, and leaving in the dark for 5 min. After adding 75 mL of distilled water to this solution and shaking to mix, it was tested by titration with a 0.1 N sodium thiosulfate solution.

RESULTS AND DISCUSSION

1. Analysis of heavy metal content and physicochemical characterization of beeswax

Table 1 shows the analysis of heavy metal contents of beeswax collected from Am and Ac, and Table 2 shows the results of analysis of different chemical properties of beeswax.

Beekeeping products are widely used as health functional foods and food additives owing to their many useful properties. However, beeswax has not yet undergone much research on its complete physicochemical properties, component analysis, or functional evaluation. In this study, we analyzed the physico-chemical characteristics of Am and Ac beeswax, which provides important baseline data for research on locally produced Korean beeswax.

The standards for heavy metals in food additives are 4.0 ppm/g for arsenic, 2.0 ppm/5 g for lead, and 1.0 ppm/0.1 g for mercury. The levels of each heavy metal measured were 0.0021 ppm/0.5 g of arsenic, 0.0031 ppm/g of lead, and 0.0034 ppm/0.03 g of mercury, all of which were confirmed to be below safety standards (Table 1). The melting point for wax from both species was 64.5℃. The esterification value appeared higher for Am beeswax at 73.73, while Ac beeswax was 79.94. The acid value of Am beeswax was more than three times higher (18.03) than that of Ac beeswax (5.88). For saponification value, Am beeswax was higher at 95.44, while Ac beeswax was at 87.41. The peroxide value was 45 times higher for Am beeswax (9.06) than for Ac beeswax (0.20). Overall, this indicates that Am beeswax has higher fatty acid content and can be dispensed rapidly in the food industry (Lim et al., 1993). Furthermore, the saponification values are higher with more free fatty acids, which means shorter fatty acid chain lengths. The higher esters for Am beeswax recorded here than for Ac beeswax suggests that Am beeswax has shorter fatty acid chains (Park et al., 2018).

This study provides baseline data on beeswax that can be used not only as a food additive but also as a functional health food material. In the future, research may expand the range of uses of beeswax by analyzing further details of the components of beeswax produced by both species and verifying the various functional effects such as anti-microorganism, anti-inflammation, anti-cancer etc.

Acknowledgments

This study was carried out with the support of RDA grant (PJ01512904).

References

-

Al-Waili, N. S. 2005. Clinical and mycological benefits of topical application of honey, olive oil and beeswax in diaper dermatitis. Clin. Microbiol. Infect. 11: 160-163.

[https://doi.org/10.1111/j.1469-0691.2004.01013.x]

-

Al-Waili, N. S., K. S. Saloom, T. N. Al-Waili and A. N. Al-Waili. 2006. The safety and efficacy of a mixture of honey, olive oil, and beeswax for the management of hemorrhoids and anal fissure: a pilot study. Sci. World J. 6: 1998-2005.

[https://doi.org/10.1100/tsw.2006.333]

-

Bogdanov, S. 2004. Beeswax: quality issues today. Bee World 85: 46-50.

[https://doi.org/10.1080/0005772X.2004.11099623]

-

Buchwar, R., M. D. Breed, A. R. Greenberg and G. Otis. 2006. Interspecific variation in beeswax as a biological construction material. J. Exp. Biol. 20: 3984-3989.

[https://doi.org/10.1242/jeb.02472]

-

Carbajal, D., V. Molina, S. Valdes, M. L. Arruzazabala, R. Mas and J. Magraner. 1998. Anti-inflammatory activity of D-002: an active product isolated from beeswax. Prostaglandins Leukot. Essent. Fatty Acids 59: 235-238.

[https://doi.org/10.1016/S0952-3278(98)90135-1]

-

Carbajal, D., V. Molina, M. Noa, S. Valdes, M. L. Arruzazabala, C. Aguilar and R. Mas. 2000. Effect of D-002 on gastric mucus composition in ethanol-induced ulcer. Pharmacol. Res. 42: 329-332.

[https://doi.org/10.1006/phrs.2000.0693]

- Chauvin, R. 1968. Traite’ de biologie de l’abeille. Paris: Masson et Cie.

-

Dumitru, C. D., I. A. Neacsu, A. M. Grumezescu and E. Andronescu. 2022. Bee-derived products: Chemical composition and applications in skin tissue engineering. Pharmaceutics 14: 750.

[https://doi.org/10.3390/pharmaceutics14040750]

-

Fröhlich, B., M. Riederer and J. Tautz. 2000. Comb-wax discrimination by honeybees tested with the proboscis extension reflex. J. Exp. Biol. 203: 1581-1587.

[https://doi.org/10.1242/jeb.203.10.1581]

- Ghanem, N. 2011. Study on the antimicrobial activity of honey products and some Saudi Folkloric substances. Res. J. Biotech. 6: 38-43.

-

Hepburn, H. R., R. T. F. Bernard, B. C. Davidson, W. J. Muller, P. Lloyd, S. P. Kurstjens and S. L. Vincent. 1991. Synthesis and secretion of beeswax in honeybees. Apidologie 22: 21-36.

[https://doi.org/10.1051/apido:19910104]

-

Kaluza, B. F., H. Wallace, T. A. Heard, A. M. Klein and S. D. Leonhardt. 2016. Urban gardens promote bee foraging over natural habitats and plantations. Ecol. Evol. 6: 1304-1316.

[https://doi.org/10.1002/ece3.1941]

-

Lewis, P. A., K. Wright, A. Webster, M. Steer, M. Rudd, A. Doubrovsky and G. Gardner. 2012. A randomized controlled pilot study comparing aqueous cream with a beeswax and herbal oil cream in the provision of relief from postburn pruritus. J. Burn Care Res. 33: 195-200.

[https://doi.org/10.1097/BCR.0b013e31825042e2]

- Lim, Y.-H., H.-Y. Lee and M.-S. Jang. 1993. Quality properties of Yu-kwa by the frying time of soybeal oil. J. Korean Soc. Food Nutr. 22: 186-189.

- Park, S. H., H. S. Shin, A. R. Kim, H. J. Jeong, S. H. Xuan, I. K. Hong, D. B. Lee and S. N. Park. 2018. Composition ratio analysis of transesterification products of olive oil by using thin layer chromatography and their applicability to cosmetics. Appl. Chem. Eng. 29: 342-349.

-

Stacey, R. J. 2001. Composition of some roman medicines: evidence for Pliny’s punic wax? Anal. Bioanal. Chem. 401: 1749-1759.

[https://doi.org/10.1007/s00216-011-5160-7]

-

Tulloch, A. P. 1980. Beeswax - Composition and analysis. Bee World 61: 47-62.

[https://doi.org/10.1080/0005772X.1980.11097776]

-

Zamora, Z., V. Molina, R. Mas, Y. Ravelo, Y. Perez and A. Oyarzabal. 2014. Protective effects of D-002 on experimentally induced gastroesophageal reflux in rats. World J. Gastroenterol. 20: 2085-2090.

[https://doi.org/10.3748/wjg.v20.i8.2085]